Camille Cambon, Issam Bendaoud, Sébastien Rouquette and Fabien Soulié

LMGC, Univ. Montpellier, CNRS, Montpellier, France

Wire + arc additive manufacturing (WAAM) process is based on layer-by-layer deposition of melted filler-wire. WAAM is a sort of 3D printer for making metallic parts. The WAAM process, under consideration in this work, uses an arc welding source to provide the heat required to melt the metallic wire. Additive Manufacturing (AM) processes are interesting alternatives to traditional subtractive processes to make medium to large size components with less waste of raw materials. AM processes make possible to produce parts with complex geometries with lower total weight than traditional machining techniques and/or to maximize the mechanical strength of the part created. However, the level of energies, building path strategies… used with the WAAM process result in distortions and residual stresses in the manufactured components that affect its fatigue life.

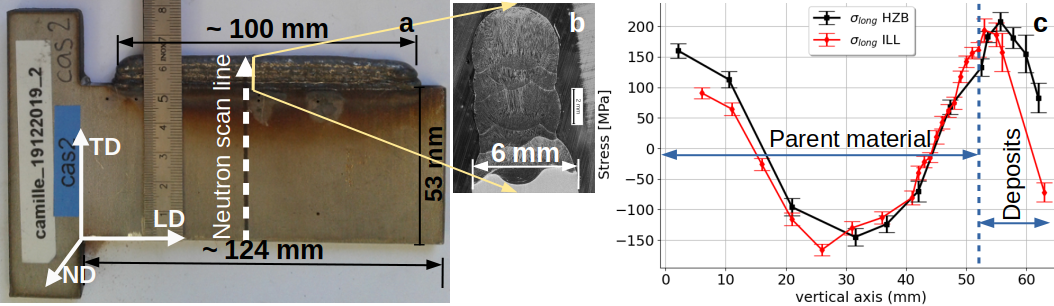

Figures : (a) specimen with 5 deposited layers on the slice of the parent material, (b) macro-graphic view of the 5 deposited layers, (c) longitudinal stress distributions along white dashed line.

The main objective of this work was to evaluate the effects of the linear energy (or heat input) on the generation of residual stresses in the manufactured specimen. The originality of these experiments relied in the geometrical choice of producing the parts: under 2D plane stress conditions (see figure (a)) as the specimen thickness of 6 mm is lower than the two other dimensions (LD and TD). Moreover, this experimental study was also designed as a WAAM benchmark as several measurements were performed online: electric signals, temperature, weld pool shape, distortions … that could be used for further comparisons with numerical simulation of WAAM. These informations were completed, off line, by macro-graphic analysis and residual stress measurements. High tensile stresses have a detrimental effect on the mechanical strength of the AM part. Stress measurements are complicated and require the use of specific equipements: x-ray diffractometer, deep hole drilling, neutron diffraction techniques …

Among these techniques, neutron diffraction is the only one able to measure stress values inside thick metallic parts without being destructive. Neutron diffraction was used to measure the stress state of our specimens, see figure (c), at different neutron facilities: HZB, Berlin, Germany and ILL, Grenoble, France. The highest stresses were measured at the parent – deposits interface. The thermal stress was the highest during the 1st deposition because the parent material was at room temperature. Furthermore, the local weld pool generated strong thermal gradient into the parent what led to a compressive stress zone within the parent. Finally, the bottom part of the specimen exhibits tensile stresses due to an upward bending of the parent as the deposited zone and top parent shortened during the cooling.

The authors acknowledge Robert Wimpory of HZB, Berlin (Germany) as well as Sandra CABEZA of the Institut Laue-Langevin, Grenoble (France) for their scientific and technical support.